K3V K5V piston pump instruction manual

Disassembly

3.3.1

Before disassembling, spread rubber sheet, cloth or similar material over the

overhaul workbench top so as to prevent parts from being damaged.

Remove dust, rust and other contaminants from surfaces of the pump with

cleaning oil.

3.3.2

Remove the drain port plug (468) and drain off the hydraulic oil from the

pump casing.

a.

Remove all plugs from both the front and rear pumps.

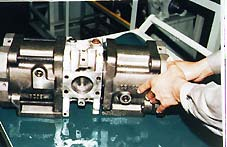

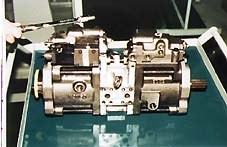

3.3.3

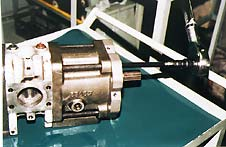

Remove the hexagon socket

headed bolts and remove regulator

from front pump.

a. Similarly, remove the regulator from

rear pump.

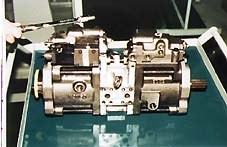

3.3.4. Loosen hexagon socket head bolts

(401) which tighten the swash plate

support (251), pump casing (271)

and valve block (312).

a.

If a gear pump or is fitted to the rear surface of the pump, then remove it

before working on the pump unit.

b.

Repeat this sequence for both the front and rear pumps.

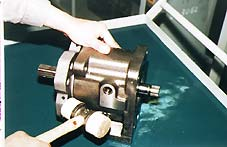

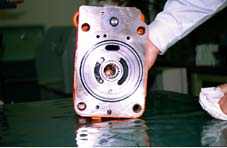

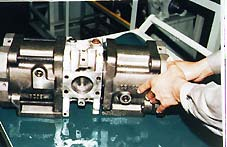

3.3.5.

Place pump horizontally on the

workbench with its regulator

mounting surface face down.

Remove the hexagon socket head

bolts (401) and separate the pump

casing (271) from it’s valve block

(312).

a

Before lowering this surface onto

the bench, spread the rubber sheet

on to the work bench so as to

prevent this surface from being damaged.

b.

Repeat this sequence for both the rear and front pumps.

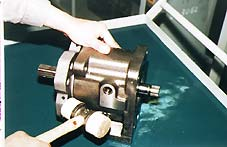

3.3.6.

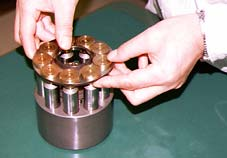

Lift the cylinder (141) out of the

pump casing (271) straight over the

drive shaft (111). Additionally

extract the pistons (151), set plate

(153), spherical bush (156) and

cylinder springs (157)

simultaneously.

a.

Take care not to damage any of the

sliding surfaces of the cylinder,

spherical bush, shoes, swash plate, etc.

b.

Repeat this sequence for both the rear and front pumps.

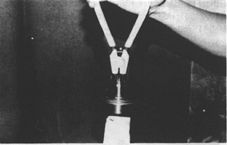

3.3.7.

Remove the hexagon socket head

bolts (406) and remove the seal cover (Front) (261).

a.

By fitting a bolt into the “pulling-out”

tapped hole of the seal cover, will

easily remove it.

b.

Take care not to damage the oil

shaft seal installed in the cover.

Similarly for the rear pump, remove the hexagon socket headed bolts on

rear pump, and remove it’s seal cover (Rear) (261) and rear cover (262).

IF a gear pump is fitted, remove this first.

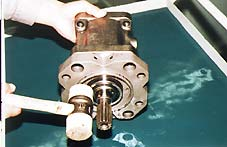

3.3.8. By tapping lightly on the flange

section of the swash plate support

(251) where it interfaces with the

pump casing side, separate the

swash plate support from it’s pump

casing.

a.

Remove the drive shaft

simultaneously with it’s swash plate support.

b.

Repeat this sequence for both the rear and front pumps.

3.3.9.

Remove the shoe plate (211) and

swash plate (212) from the pump casing (271).

a.

Repeat this sequence for both the

rear and front pumps.

3.3.10. Tapping lightly on the external shaft

end of drive shafts (111, 113) with

plastic hammer, extract each drive

shaft from it’s swash plate support.

If required, extract the rolling

bearing (123), bearing spacer (127),

and snap ring (824) from the drive shaft (111,113).

a.

Repeat this sequence for both the

rear and front pumps.

b.

Don't reuse the bearings that you have extracted.

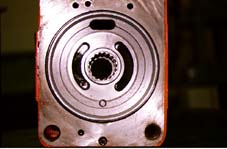

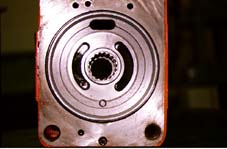

3.3.11.

Remove the valve plates (313, 314)

from the valve block (312).

a.

These may be removed during

sequence 5.

If required, execute sequence 12 and 13.

3.3.12.

Remove the stopper (L)(534), stopper (S)(535), servo piston (532) and tilting

pin (531) from pump casing (271).

a.

In removing the tilting pin, use a protection shield to prevent the pin head

from being damaged.

b.

Loctite has been applied in production to the fitting areas of the tilting pin

and servo piston, so care must be taken to prevent servo piston damage.

3.3.13. Remove the needle bearing (124)

and spline coupling (114) from the valve block (312).

a.

Don't remove the needle bearing

unless it definitely requiresreplacement.

b.

Don't loosen the hexagon stroke

adjustment nuts of valve block or

swash plate support. If loosened,

the flow setting will be changed

---------------------------------------------------------------------------------------------------------

3.4. Assembly Procedure

3.4.1.

Fit the servo piston (532), tilting pin (531), stopper (L)(534) and stopper

(S)(535) to the pump casing (271).

a.

In tightening the servo piston and tilting pin to the pump casing, use a

protector to prevent the tilting pin head and feedback pin from being

damaged.

b.

Apply loctite (medium) to the

threaded section of tilting pin and

servo piston and allow to set.

3.4.2.

Fit the swash plate support (251) to

it’s pump casing (271), by tapping

the former lightly with a hammer.

a.

Repeat this sequence for both the

rear and front pumps.

3.4.3.

Place pump casing with its

regulator-fitting surface down on the

bench. Fit the tilting bush of the

swash plate to it’s tilting pin (531),

and then fit the swash plate (212) to

it’s swash plate support (251)

correctly. Simultaneously fit the O-ring.

a.

Confirm with ones fingers that the

swash plate is bedded down correctly by ensuring that it could be removed

smoothly.

b.

Apply grease to the sliding sections

of the swash plate and swash plate

support, and then smoothly fit the

drive shaft through it.

c.

Repeat this sequence for both the

rear and front pumps.

In the case that one has

disassembled the roller bearings

then sequence 4 and 5 should be followed.

3.4.4.

Install the bearing spacer (127) on

to the drive shaft (111,113), and

then next install the roller bearing

(123) to this drive shaft.

3.4.5

Install the snap ring (824) onto the

drive shaft (111,113).

3.4.6.

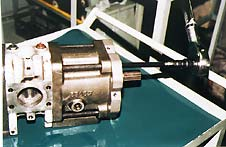

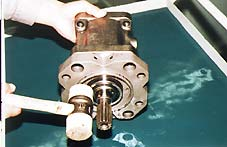

Fit the drive shaft assembly

(complete with bearing (123),

bearing spacer (127) and snap ring

(824)) to it’s swash plate support (251).

a.

Do not tap the drive shaft with a

hammer as damage may occur.

b.

Assemble the shaft assembly into

it’s support by tapping the outer

race of bearing lightly with plastic

hammer. Fit them fully, using steel bar or so on.

c.

Repeat this sequence for both the rear and front pumps.

In the case that an oil seal has

been replaced follow sequence

3.4.7.

Install the new oil seal (774) into the

seal cover (F)(261) and seal cover ((R)(263).

3.4.8.

Assemble the front seal cover

(F)(261) into the pump casing (271)

and fix it with the hexagon socket

head bolts (406). Similarly,

assemble the rear seal cover

(R)(261) or rear cover (263) into

pump casing (271) and fix it with

hexagon socket head bolts.

a.

Apply grease lightly to the oil seal

within the seal cover.

b.

Assemble them carefully, taking full care not to damage the oil seal.

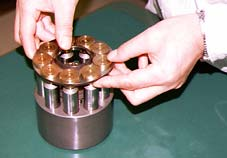

3.4.9. Install the cylinder springs (157), spacer

(158) and spherical bush (156) onto the

cylinder (141). Fit the pistons (151) and

shoe (152) through the set plate (153).

a.

Repeat this sequence for both the

rear and front pumps.

3.4.10

Assemble the piston shoe

(151,152) and set plate (153) group

onto and into the cylinder bores of

the cylinder (141), springs (157),

spherical bush (156) and spacer (158) group.

a.

Repeat this sequence for both the

rear and front pump

3.4.11.

Fit the splined phases of the

retainer and cylinder sub-assembly

into the pump casing.

a.

Repeat this sequence for both the

rear and front pumps.

b.

If the needle bearing has been

replaced then follow sequence 12.

3.3.12 2

Install the needle bearing (124) and

splined coupling (114) into the

valve block (312).

3.4.13.

Fit the valve plate (313) on to the

valve block (312), utilising the

location pin.

a.

Take care not to the mistake the

suction and delivery directions of

the valve plate.

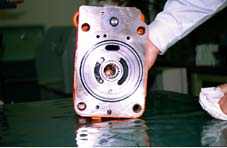

3.4.14.

Fit the valve block (312) to it’s p

casing (271) , and tighten the

hexagon socket headed bolts (401).

Simultaneously install the O-Ring.

a.

Repeat this sequence for both the

rear and front pumps.

b.

It is easiest to assemble the rear

pump first.

c.

Take care not to mistake the Valve plate / Valve Block direction of rotation.

NOTE: For clockwise rotation (viewed from input shaft side)

Fit the valve block with the regulator up and with the delivery flange

left, when viewed from shaft end.

NOTE: For counterclockwise rotation (viewed from input shaft side)

Fit the valve block with the regulator up and with the delivery flange

on the right side, when viewed from the shaft end.

3.4.14.

Place the feedback pin of tilting pin

into the feedback lever of regulator.

Then fit the regulator and tighten

the hexagon socket head bolts.

a.

Take care not to mistake the

regulator of the front pump for that

of the rear pump.

3.4.15.

Fit the drain port plug (468).

a.

Repeat this sequence for both the rear and front pumps.

This concludes the reassembly procedure.

Source Download(PDF)