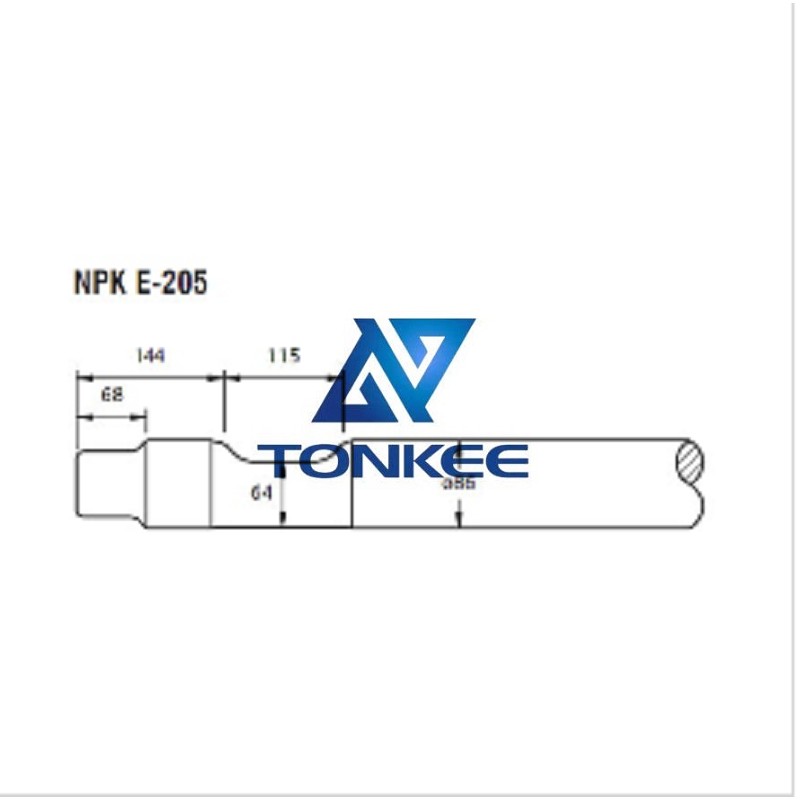

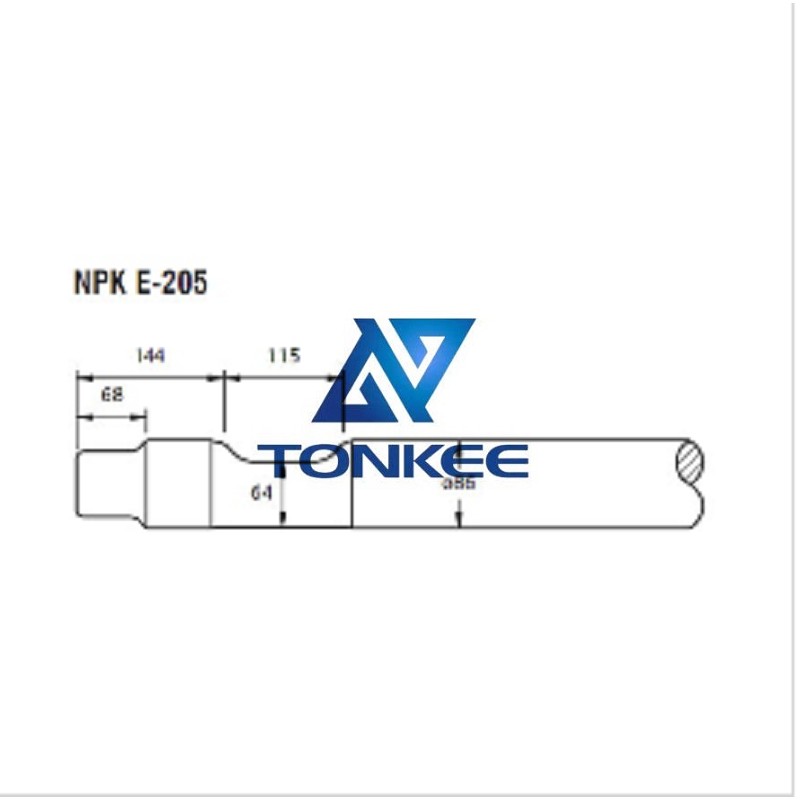

The key component of the NPK E-205 is its 86mm chisel.

Constructed from premium-grade, heat-treated steel, the chisel is exceptionally strong and resistant to wear, ensuring longevity and reliability during intense hammering operations. With its larger size compared to the E-204 model, the E-205 is capable of delivering even more force and impact energy, allowing it to tackle tougher materials such as reinforced concrete and thick rock layers.

The hydraulic system of the NPK E-205 enables precise and efficient operation. Powered by an external hydraulic power source, such as a hydraulic excavator or backhoe loader, the breaker utilizes hydraulic pressure to generate high-impact forces. These forces are then transmitted through the chisel, enabling it to break through the toughest surfaces effectively.

One notable feature of the NPK E-205 is its adjustable blow frequency and power settings. This flexibility allows operators to customize the performance of the breaker to match specific job requirements. Whether it's a delicate demolition task or a more demanding application, the E-205 can be tailored to deliver optimal power and efficiency, enhancing productivity on the job site.

To ensure safety and reliability, the NPK E-205 is equipped with various safety features.

These may include a pressure relief valve that protects against overloading, a cushioning system that reduces shock and vibration, and a noise reduction mechanism to minimize sound levels. These features not only enhance operator safety but also contribute to a more comfortable working environment.

Maintenance and servicing of the NPK E-205 are designed to be user-friendly and efficient. The breaker is engineered with easy access to critical components, including the chisel and wear parts, enabling quick replacement and reducing downtime. Routine inspection, lubrication, and adherence to the manufacturer's maintenance guidelines are essential to ensure the breaker's optimal performance and extend its lifespan.